Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

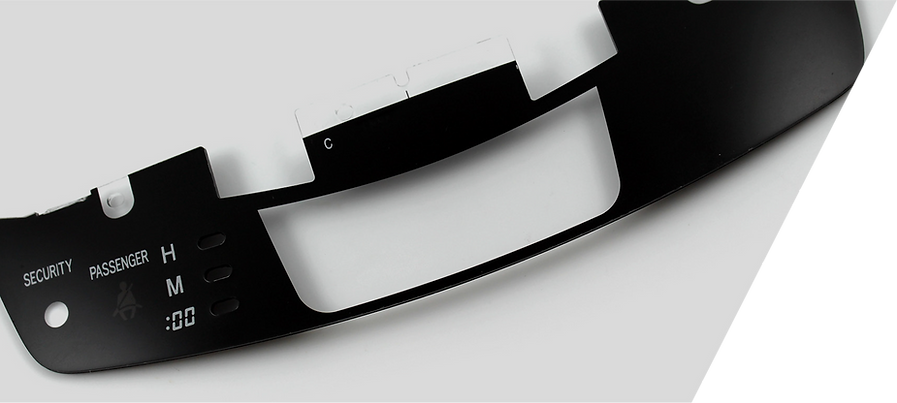

TASUS employs multiple secondary processes for the decoration of injection molded automotive components, including screen and pad printing, and hot stamping. Beyond these secondary processes and in the spirit of continuous improvement In-Mold Decoration (IMD) techniques are used for reduced production time by reducing the number of secondary processes required. These methods include automated insertion of in-mold foils and insert molding of both flat and preformed films. Multiple colors can be decorated in a single operation, offering significant improvement over traditional pad-printing techniques.

IN-MOLD DECORATION

FLAT AND PREFORMED

Insert-Mold Decoration (IMD) is the process of inserting a graphic overlay into an injection mold, uniting the advantages of functional and unique graphics with plastic molded components, becoming an integral part of the assembly. Ranging from the simple bonding of printed labels during the molding process, to the use of a screen printed or hard coated film, we manufacture exclusive products utilizing custom techniques. The IMD process is cost effective, as accuracy is increased and wasteful steps are eliminated.

IMD

TRANSFER TYPE

Our IMD technique involves the injection of molten resin into a specially designed mold, in which a label becomes an integral attribute of the plastic wall of the molded part. It is then developed into a semi-permanent imbedded component of the object. This specialized process reduces costs by eliminating expensive adhesives.

INSERT MOLD

THERMOFORMING

Thermoforming consists of a film held in a rigid frame and heated to its plastic flow point. A combination of vacuum, air, and mechanics forces the film into the correct shape. Benefits include; greater design flexibility, improved recyclability of materials, selection of finish options, including texturing, lower costs than traditional methods, option for backlighting.